Almost all process cooling systems involve water, which over time accumulates dust, sand, pollen, algae, and pipe scale particles that originate from cooling towers and makeup water. In extreme cases, particle buildup clogs entire systems, requiring shutdowns, expensive maintenance, repair, or replacement.

A buildup of solids no thicker than a human hair inside piping can reduce heat transfer by up to 30%, drastically reducing efficiency and increasing energy consumption. High efficiency removal of fine particles and suspended solids can reduce maintenance and operating costs while improving your organizations bottom line!

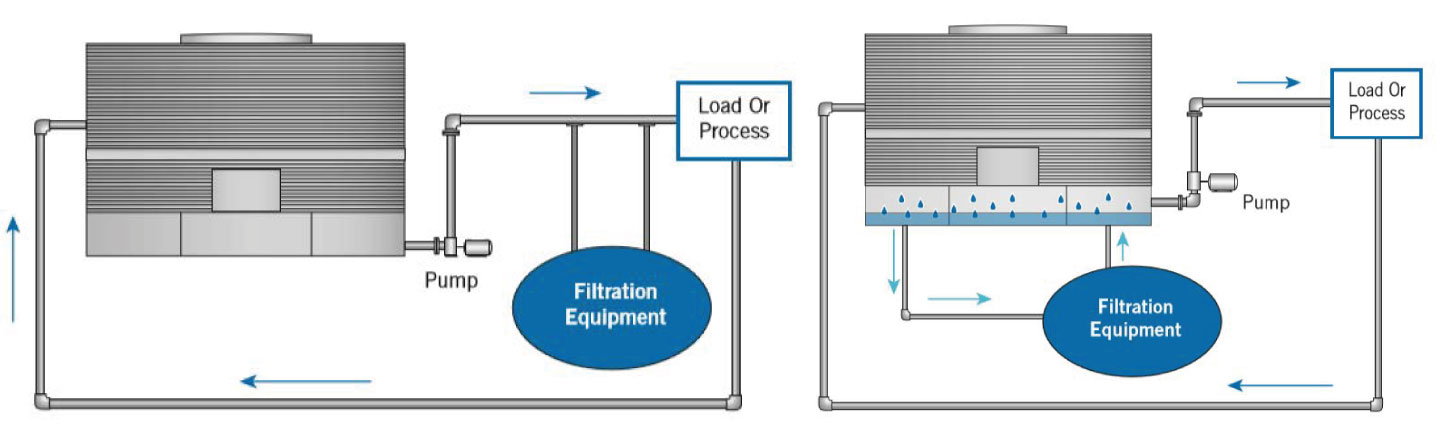

FULL STREAM FILTRATION SIDE STREAM FILTRATION

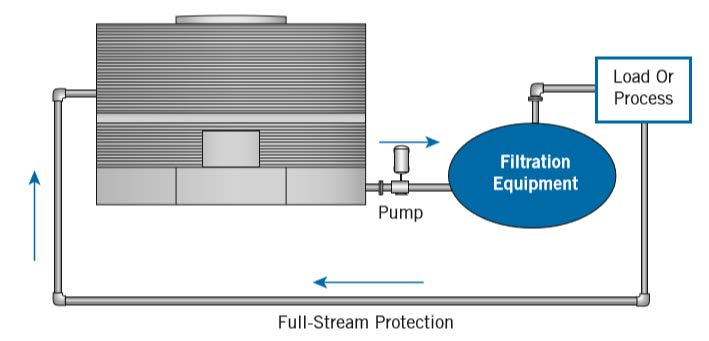

FULL STREAM FILTRATION

In full flow cooling tower filtration, a filter is installed after the cooling tower on the discharge side of the pump. Thereby extending equipment life and maintaining design heat transfer efficiencies on new and existing equipment.Our cooling tower filters are sized to handle a system’s design flow rate such that the cooling tower filter will continuously clean the entire system flow.The meaning that the filter must be sized to handle the system’s design flow rate

Full Stream Filtration Benefits :

There are numerous benefits to circulating the clean water that results from effective cooling tower water filtration;

- Reduced energy consumption,

- Improved chemical performance,

- Lower maintenance cost,

- Full flow filtration reduces heat exchanger and chiller maintenance significantly and improves the operating cycles of the equipment as well

- Improved productivity with less downtime,

- Control of biological growth.

SIDE STREAM FILTRATION

Side stream filtration is a cost-effective alternative to full flow filtration because it continuously filters a percentage of the flow instead of the entire flow. Side stream filtration can reduce maintenance and improve operating cycles of equipment in the cooling loop. This method involves removing particles at a higher rate than accumulation. Over time, filtering 1% - 10% of the cooling loop flow results in the filtration of the total volume of water every 12 – 72 hours. Keep in mind, the filtration rate will highly depend on the application and filtration technology at hand.

Selecting the right side stream filtration system will depend on:

- The quality of make-up water added to the system.

- The type of contaminants already in the system and/or being generated within the system.

- The current chemical treatment program.

- The cycles of concentration at which the system is operating.

- The maintenance and operating requirements.

- Budget constraints

Side Stream Filtration Benefits :

- Your chemical treatment program will yield improved results.

- The removal of abrasive suspended solids will aid in reducing the potential for erosion and corrosion.

- Over time, you will experience reduced maintenance costs and chemical consumption.

- Resulting in improved heat-transfer efficiencies and reduced energy costs.

- One key advantage over full flow filtration is that the side stream filtration system can be cleaned without having to go offline, resulting in no planned downtime for maintenance.